The All Geared Lathe Machine is mostly used in a variety of industries for the purpose of carrying out a variety of metal shaping operations. A lathe can conduct a wide variety of machining operations, which enables it to produce components with the characteristics that the user specifies. On a lathe, various operations are accomplished by changing the tool ends and adjusting the mechanical connection existing between the tool and the workpiece.

An All Geared Lathe Machine essentially features a gearbox with a lead screw and feed shaft that boosts its capacity for milling. There is a large variety of all-geared lathe machines available, and they come in a variety of weight capacities, including light-duty, medium-duty, heavy-duty, and extra-heavy-duty. In tool rooms, low-volume metal shaping jobs are often completed on a light-duty lathe, whereas medium- and heavy-duty lathe machines are typically selected for industrial applications involving bulk metal forming.

Tracing The Roots!

The first iteration of the lathe machine, which was invented at an earlier point in time, was a simple, manually controlled device that was fitted with fundamental capabilities for performing routine material reshaping operations. The first lathe machines were only capable of reshaping and creating the cylindrical components out of hard materials such as wood, plastics, metal, and so on.

These components could then be used in the machine. In subsequent years, however, with the development of newer technologies, lathes became more sophisticated, equipped with a number of intricate features and components, which made it possible to do a greater range of jobs, as well as those that were more difficult, with relative ease.

The Different Configurations of All Geared Lathe Machine!

Today All Geared Lathe Machine Manufacturers design different lathe machine configurations. For instance, there are lathe machines developed particularly for lighter operations, as well as lathe machines that are heavy duty and designed primarily for big workloads or bulk shaping operations and may be applied with ease.

There are machines that are meant to be operated manually, and there are other machines that are built for entirely automated, more rapid, and precise operations. The fully geared lathe machine is one example of this kind of lathe, built for precision and speed in the process of material shaping operations.

We Are The Leading Exporters!

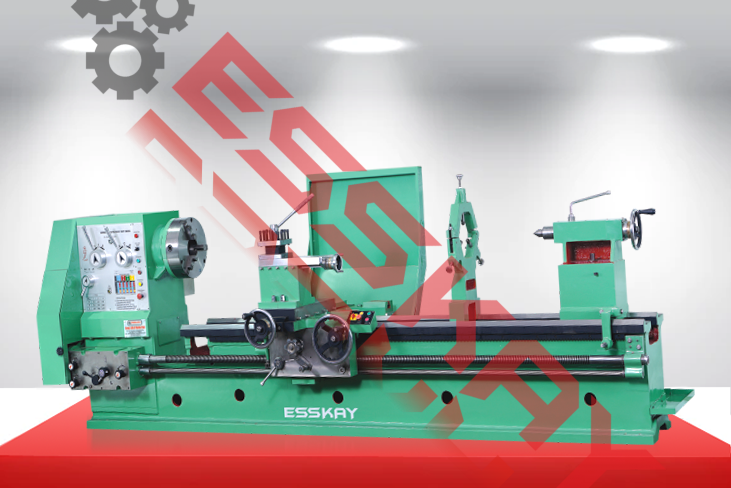

ESSKAY Lathe And Machine Tools export some of the finest quality indigenously manufactured all-geared lathe machines. We are the top All Geared Lathe Machine Exporters In India. We have exported our machines to fifteen plus countries with higher levels of customer satisfaction. Visit our website for further information about us.